What are Hybrid Ships: Over the past ten years, the popularity of hybrid ships has skyrocketed as ship owners look to cut expenses and decarbonize their fleet. Hybrid boats generate power for movement and stationkeeping using a minimum of two propulsion systems, often diesel and batteries. With this combination of power sources, vessels can benefit from smoother operation, zero emissions when station-keeping, and long-range diesel power with short-term electric power bursts. We’re going to examine hybrid vessels more closely today, including their operation and where they fall between fully electric and diesel vehicles.

What are Hybrid Ships?

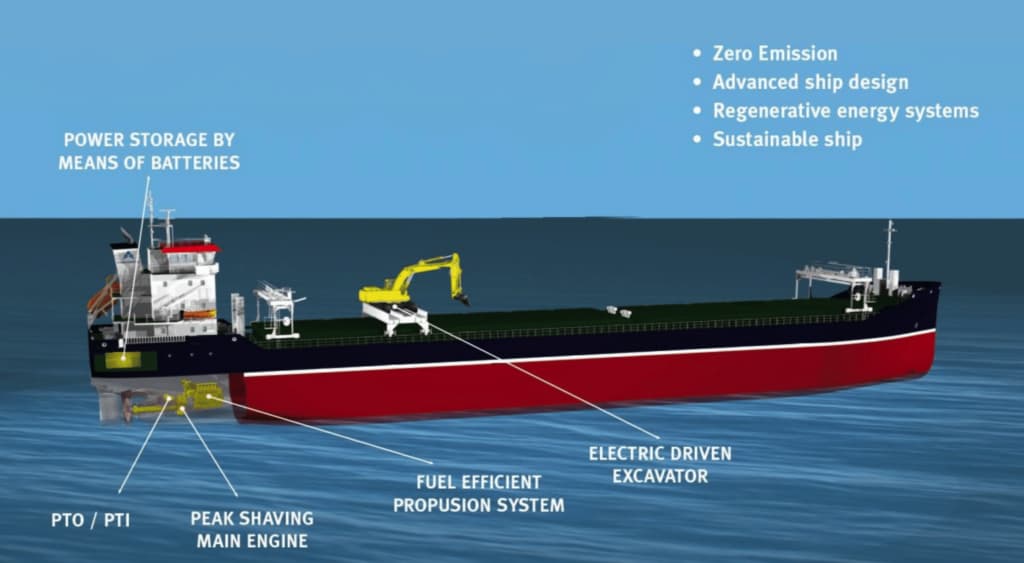

Fundamentally, an electric battery system and an engine propel hybrid boats. As the ship moves and uses up extra energy, these systems are replenished and stored in battery packs. Then, when the power level drops, the batteries can supply more energy for optimal shaving or run the vessel entirely.

Dynamically positioned ships benefit from hybrid power because they can maintain station without lowering anchors, keep exact location, or move along a precise path by controlling thrusters. Construction and maintenance of offshore wind farms, research, and rigs can be done with these boats. By running entirely on electricity, pollution is reduced and problems caused by low-demand generators are avoided. The reduction in vibration will also make it more comfortable for people working, sleeping, or conducting research on board.

Diesel and electric batteries are the two main sources of power for hybrid ships. Depending on the vessel, diesel direct drive can be used at lower power and diesel electric at higher power. They can be bigger, like an offshore support vessel, or smaller, like an inland ferry. While battery power can be retrofitted into older boats, many new vessels are designed with hybrid operation in mind.

Businesses such as Wärtsilä provide hybrid retrofits for already-built ships. One example of a hybridized ship is the Hagland Shipping AS Hagland Captain, a short-sea shipping vessel. Vard Electro offers turnkey hybridization systems, such as the SeaQ Energy Storage System (ESS), and frequently uses them in retrofits. As seen by the Rolls-Royce Marine battery containers below, many of these new systems are simple to install, and some can even be containerized for an almost drop-in installation.

Why utilize a hybrid propulsion system?

The use of battery hybrid power began in the 2010s as a means of improving workboat and ferry fuel efficiency. The solutions have estimated fuel savings of between 10 and 20 percent, but that is just one benefit. When using a battery hybrid system, vessels should be tested to operate in closed bus mode, which can result in annual cost savings of hundreds of thousands of dollars.

During short spikes in demand, peak load shaving assists battery systems, which lessens the load on generators. Battery power is also available on most ships when entering and exiting ports and when performing dynamic positioning. By reducing the load on generators and enabling safe shutdowns, maintenance expenses are reduced. Furthermore, electric driving reduces vibration, increasing passenger comfort.

Hybrid ships can reduce emissions by 10–30% compared to conventional diesel-fueled ships in recent years. By 2050, shipping wants to reduce its carbon footprint by half, and BP and Shell have committed to becoming carbon neutral by then. Hybrid battery electric systems are becoming more popular due to their ability to yield financial and environmental benefits.

Electric systems and pure electric vessels are becoming more popular thanks to hybrid systems. Energy-dense, emissions-free, smooth-running electric generators are a benefit of hybrid propulsion.

Understanding the Different Decks on Cruise Ships and Their Functions

Basically, there are two ways to make use of the extra power that batteries provide:

I) Enabling the primary engine to run within the specified rating without needless spikes and meeting all requirements at full operation and service.

Technically speaking, this is referred to as “peak-shaving,” which, put simply, is the process of controlling erratic and rapid fluctuations in power needs.

As a result, in fully functional hybrid ships, the main engine or propulsion system does not need to work as hard when there is an unexpected increase in power needs, such as when the ship speeds up to reduce travel time or when it needs to combat bad weather at sea. As a result, the primary engine keeps running at its best rating.

II) Meeting the vessel’s full load needs under reduced power scenarios, as previously indicated. For ships used for activities such as research or offshore, where a large amount of low-power operations take place while the ship is stationary.

Many contemporary designs use battery power either entirely or in part for technologies such as thrusters or DPS (dynamic positioning systems), as well as for other functions like deck cranage, cargo equipment, air conditioning, pumping, and hotel loads (internal electrical power requirement for daily operations in a vessel). This is referred to as “spinning reserve” when the battery load completely replaces or substitutes the main engine load.

When necessary, hybrid ships’ mechanisms allow them to concurrently deploy both power supply or switch between them.

The batteries are typically heavy-duty, industrial batteries, primarily of the Lithium-ion kind, however we do not delve into the specifics of the batteries. Depending on the needs and size of the ship, these batteries are capable of providing thousands of kilowatts of electricity in continuous cycles.

A series-parallel combination connection powers the majority of these batteries, allowing for the provision of sufficient power from a single supply line and the unaffected continuation of the supply in the event of a line failure. Do you recall the series-parallel relationship from your basic physics courses?

How are these batteries periodically recharged?

This takes us to two frequent configurations found in hybrid ships:

- Plug-in Hybrid Ship: This is comparable to a plug-in hybrid vehicle that uses recharging units at a station to replenish its batteries. Similar to this, plug-in hybrid ships use shore power to recharge their batteries while berthed at a dock or terminal. The battery packs contain this energy. These ships are very uncommon for really long-distance operations because the charge in the battery capacitors is only usable for a certain number of days, and recharging is necessary.

- Conventional Hybrid Ships: These ships don’t need to regularly refuel on land. Generators, alternators, and other devices that draw power from the primary engine or the auxiliary engines can be used to replenish the batteries. This is a mutually dependent design in which the batteries share the high or peak load requirement of the engine(s) and are dependent on the conventional engines for recharging.

Batteries are frequently recharged when operating at maximum power, when the excess energy is put to use for charging. Long-distance vessels benefit from this setup.

Different types of vessels use hybrid power; batteries are typically used at low power and direct diesel drives are used at higher power.

As previously mentioned, a combination of both can also be employed as and when the circumstance calls for it.

A hybrid ship might be as big as an offshore support vessel or as little as a coastal ferry. The installed battery power ought to be commensurate with the vessel’s size and total loading or power consumption requirements.

This means that, for a hybrid ship of a given size and engine, the battery arrangement should be such that, in the worst-case scenario, the minimum amount of electric power it is capable of producing will be enough to meet the maximum peak loads by supplementally powering the engine without pushing it over its rated limit, as well as meet the operational requirements at low power as desired.

Therefore, the choice of the primary engine and the needs for battery powering for a specific hybrid ship design and operationality should be made simultaneously.

Even new vessels are being designed with hybrid capability, many of which are old or existing vessels. A 1600 KW battery system was recently added to the Viking Energy, a dual-fuel vessel built in 2003.

Best decks on Cruise: Factors to Consider for an Enjoyable Cruise Experience

Benefits of Hybrid Ships and Their Future

Any discussion on hybrid propulsion and ships needs to take into account their benefits.

Aside from the minor disadvantage of being somewhat more expensive to install for larger vessels (which is, nonetheless, greatly outweighed by the savings that follow during service), hybrid ships’ benefits are the primary factors drawing interest from shipowners and operators worldwide.

- Fuel economy is the primary and most significant benefit of hybrid propulsion. Effective hybrid systems have demonstrated fuel savings of between 15% and 20% when compared to conventional diesel-only power. Additionally, the percentage has increased for smaller-sized boats by up to 30%. Even on larger ships, Viking Energy claims to be able to save fuel by up to 25–28% using hybrid propulsion. Operating entirely on electricity in low power scenarios, absorbing peak loads, and maintaining the engine within optimal limits can reduce fuel consumption. This adds up to significant energy savings, making it extremely cost-effective for owners and operators without sacrificing operational effectiveness.

- Lower emissions are another extremely important benefit that results from this, and they do so for the same reasons as mentioned in the previous point. As this article’s introduction states, efficient fuel use equates to lower levels of carbon and other harmful emissions. Decarbonization and emissions reductions ranged from 20 to 30 percent, depending on the type of vessel. Because they are more environmentally friendly, hybrid ships are becoming more and more popular.

- Efficiency of propulsive action: One of the best examples of propulsive efficiency is an engine that is always operating at maximum load.

- Flexibility: having a dependable electrical backup in case the primary power source fails, as well as the ability to switch between powering modes if necessary.

- less vibration and noise when compared to traditional propulsion.

Without a doubt, one of the innovative innovations in the maritime industry is hybrid propulsion. There is still more work to be done, even though many new vessels are being built as hybrids and many older ones are being converted to meet energy efficiency regulations. Its future is undoubtedly bright and environmentally friendly.